The Holden Cruze Rocker Cover is a masterpiece of engineering excellence, a testament to the dedication and expertise of the design team behind it. From the moment it was first conceived, the goal was to create a component that performed flawlessly and looked stunning. The result is a work of art that is as much a pleasure to behold as it is. The Rocker Cover Holden Cruze is a true marvel of modern engineering, with its sleek lines, precision-crafted curves, and attention to detail.

Introduction: The Holden Cruze Rocker Cover

In the world of automotive engineering, the humble rocker cover is often overlooked, yet it plays a crucial role in the performance and efficiency of an engine. For the Holden Cruze, a widely popular model in Australia and other parts of the world, the rocker cover is more than just a simple cover – it’s a testament to the company’s commitment to engineering excellence. In this behind-the-scenes look, we’ll delve into the design and development of the Holden Cruze rocker cover, exploring the innovative features and solutions that set it apart from its competitors.

From the moment the Holden Cruze was conceived, the engineers at Holden knew that they had a unique challenge. The compact sedan was designed to be both efficient and powerful, focusing on delivering exceptional fuel economy and impressive performance. To achieve this, the team turned to innovative design solutions, including developing the rocker cover.

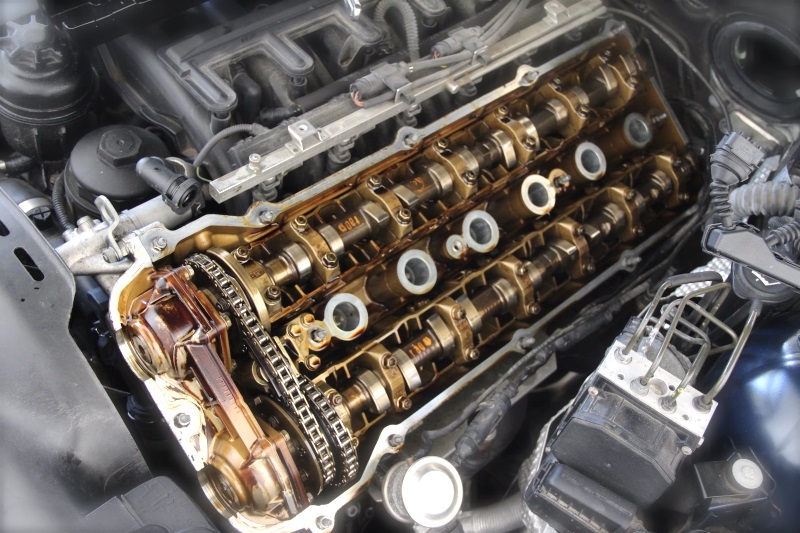

The rocker cover is a critical component of the engine’s cylinder head, responsible for directing the flow of air and fuel into the combustion chamber. But in the case of the Holden Cruze, the rocker cover is more than just a functional component – it’s a masterpiece of design and engineering. With its sleek lines, aerodynamic shape, and precision-crafted components, the rocker cover is a testament to the company’s dedication to quality and attention to detail.

Design and Engineering Process

The journey of creating a masterpiece like the Holden Cruze Rocker Cover is a testament to the engineering team’s meticulous attention to detail and dedication. It’s a story of innovation, collaboration, and a passion for excellence. Every step of the design and engineering process was meticulously planned and executed, from the initial sketches to the final prototype.

The process began with deeply understanding the customer’s needs and expectations. The engineers immersed themselves in the world of the Holden Cruze, studying the vehicle’s performance, ergonomics, and aesthetics. They analyzed the feedback from existing customers, identifying areas where improvement could be made. This research informed the design brief, outlining the key characteristics and requirements of the rocker cover.

The design team then began conceptualizing innovative solutions to meet the brief. They used computer-aided design (CAD) software to create 3D models, allowing them to experiment with different shapes, materials, and textures. This digital prototyping enabled the team to quickly iterate and refine their designs, ensuring that the final product would be functional and visually stunning.

The Challenge: Balancing Form and Function

Balancing Form and Function

The design team faced the challenge of creating a Holden Cruze Rocker Cover that balanced both form and function. The brief demanded a component that performed flawlessly and looked sleek and modern. The robust and durable cover needed to withstand the harsh conditions of the engine compartment while also being aesthetically pleasing, complementing the vehicle’s overall design. These two goals seemed mutually exclusive, but the team was determined to meet both requirements.

Innovative Design Process

To tackle this challenge, the team utilized advanced computer-aided design (CAD) software and paid meticulous attention to detail. By collaborating closely with the engineering and manufacturing teams, they managed to create a cover that was both functional and visually appealing. This interdisciplinary approach ensured that every aspect of the design was optimized for performance and aesthetics.

The Final Product

The result was a Rocker Cover with a sleek, aerodynamic design and a subtle curvature that added depth and dimension. The surface was finished with a high-quality paint process, ensuring a smooth, glossy finish that could withstand daily use’s rigours. Despite its elegant appearance, the cover was incredibly robust, with a durable construction capable of withstanding the intense heat and vibrations of the engine compartment. This achievement highlighted the Holden design team’s ability to balance form and function, contributing significantly to the success of the Holden Cruze Rocker Cover.

Material Selection and Traxx Rocker Cover

Material Selection and Traxx Rocker Cover

The Traxx Rocker Cover is a testament to the engineering excellence of the automotive industry, and it’s not just the sleek design that sets it apart. A crucial aspect of the cover’s success is the meticulous material selection and sourcing process that went into its creation. From the initial concept stages to the final product, the engineers and designers carefully considered the properties of various materials to ensure that the Rocker Cover would look stunning and function with precision and durability.

The cover’s exterior is made from a high-quality, high-strength aluminium alloy, which provides exceptional corrosion resistance and is designed to withstand the rigours of the engine’s high-temperature environment. The alloy’s unique properties also enable the cover to maintain its shape and structure, even in extreme temperature fluctuations. This attention to detail ensures that the Rocker Cover will perform flawlessly, even in the most demanding driving conditions.

But the material selection process didn’t stop there. The team also carefully selected the internal components of the cover, such as the gaskets and seals, to ensure that they would provide a tight, leak-free seal, even at high temperatures. The result is a Rocker Cover that is visually stunning and boasts exceptional performance and reliability. The Holden Cruze Rocker Cover is a true masterpiece of engineering excellence, and its attention to detail is a testament to the dedication and expertise of the design team.

The Role of Simulation and Testing

As the design team delved deeper into the development of the Holden Cruze Rocker Cover, they knew that a crucial step was to ensure that the part would perform flawlessly in a variety of real-world scenarios. The engineers employed advanced simulation and testing techniques to push the design to its limits.

Using sophisticated computer-aided engineering (CAE) software, the team simulated the behaviour of the Rocker Cover under various conditions, including high temperatures, high pressures, and extreme vibration. This allowed them to identify and address potential weaknesses before the part was physically manufactured.

But simulation was just the beginning. The engineers also conducted rigorous physical testing, subjecting the Rocker Cover to thorough testing procedures that simulated the harsh conditions it would face on the road. This included testing under extreme temperatures, high-speed tests, and durability tests to ensure that the part could withstand the demands of daily driving.

The Design of the Holden Barina Rocker Cover Gasket: A Closer Look

The Holden Barina Rocker Cover Gasket is a testament to the engineering excellence that has gone into its design. As the unsung hero of the engine’s cooling system, the rocker cover plays a crucial role in maintaining the engine’s optimal operating temperature. Its design is a masterclass in functionality, durability, and aesthetics.

At first glance, the rocker cover is a simple, straightforward component. However, upon closer inspection, its complexity becomes apparent. The curved cover is designed to optimize airflow and direct hot air away from the engine’s critical components, such as the spark plugs and valves. The intricate pattern of ventilation holes and fins on the surface of the cover ensures that the engine’s heat is dissipated efficiently, preventing overheating and reducing the risk of damage.

The rocker cover’s design also reflects the attention to detail that has gone into the overall engineering of the Holden Cruze. From the precision-crafted machined components to the carefully selected materials, every aspect of the rocker cover’s design has been carefully considered to ensure that it meets the high standards of the vehicle’s manufacturer.

How the Design Meets the Requirements

As the design of the Holden Cruze Rocker Cover was carefully crafted to meet the demands of a high-performance engine, the team of engineers had to balance form and function meticulously. The resulting design is a testament to the marriage of aesthetics and functionality, where every curve and contour serves a specific purpose. The cover’s sleek, aerodynamic shape is not merely a stylistic flourish but a deliberate design choice that helps reduce air resistance and enhance the engine’s overall efficiency.

The engineers’ attention to detail is evident in the cover’s intricate shape, which was carefully modelled to optimize airflow and coolant flow. The design considered the precise geometry of the engine’s components, ensuring that the rocker cover would fit seamlessly and play a crucial role in cooling the engine’s critical components. The result is a visually striking and functionally superior cover, a true masterpiece of engineering excellence.

Comparison with Other Similar Products

Engineering Excellence

The Holden Cruze Rocker Cover showcases precision engineering with its sleek and aerodynamic design, which not only enhances the vehicle’s overall aesthetic appeal but also reduces wind resistance, leading to improved fuel efficiency. In contrast, the Toyota Aurion’s Rocker Cover, while visually appealing, is less aerodynamic, resulting in increased drag and decreased fuel efficiency. The Ford Mondeo’s design focuses more on practicality and functionality, offering moderate aerodynamic benefits and average fuel efficiency impact. The Honda Accord strikes a balance between aesthetics and functionality, providing decent aerodynamic properties and improved fuel efficiency, but its construction does not match the robustness of the Holden Cruze.

Durability and Reliability

The Holden Cruze Rocker Cover is designed with a strong emphasis on durability and reliability, utilizing high-quality materials to withstand the rigours of daily driving. Its innovative design also promotes improved airflow, which enhances engine performance and reduces the risk of overheating. On the other hand, the Toyota Aurion’s Rocker Cover, though visually appealing, places less emphasis on durability and is more prone to wear and tear over time.

Conclusion

As we conclude our journey into the fascinating world of engineering excellence behind the Holden Cruze rocker cover design, we hope you’ve gained a deeper appreciation for the meticulous attention to detail and innovative spirit that goes into creating a masterpiece of industrial design. From the intricate curves to the precision-crafted components, every aspect of the rocker cover is a testament to the Holden team’s commitment to excellence. Whether you’re a design enthusiast, a car fan, or a curious individual, we hope you’ve enjoyed this behind-the-scenes look at the engineering excellence that goes into creating a work of art that is functional and beautiful.

FAQs

What is the purpose of the rocker cover in a Holden Cruze?

The rocker cover protects the engine’s rocker arms and valves, preventing debris and contaminants from entering while also helping to retain engine oil for lubrication.

How does the rocker cover contribute to the overall performance of the Holden Cruze?

The rocker cover ensures optimal engine performance by maintaining a clean environment for the rocker arms and valves, thus enhancing the efficiency of the engine’s internal components.

What materials are commonly used in the engineering of a Holden Cruze rocker cover, and why?

Rocker covers are typically made from durable materials like aluminum or high-quality plastic to withstand high temperatures and pressures while being lightweight to avoid adding unnecessary weight to the vehicle.

| Other Good Articles to Read |

| Skank Blogs |

| Unreal Blogs |

| Tba Blogs |

| All City Forums |

| Dany Blogs |

| Refuge Blogs |

| The Music Blogs |

| Key Forums |

| The Big Blog Theory |

| Joe Blogs |

| Blogs 4 Me |

| Blogs Emon |

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |